Reasons to Use Deaerator for Boiler Feed Water in Plants

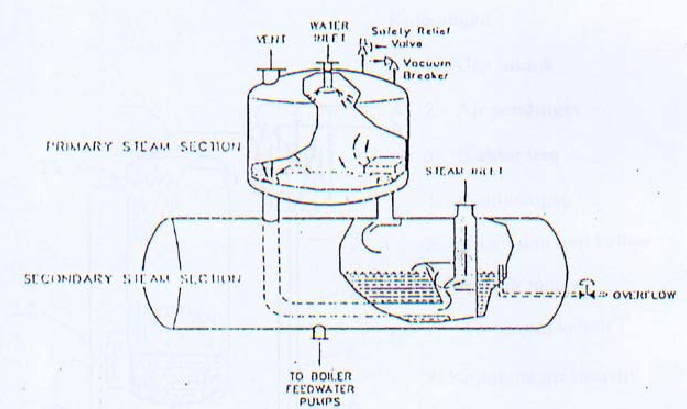

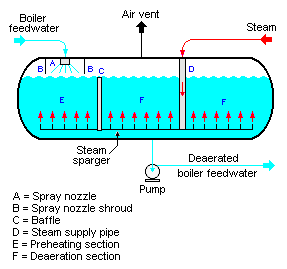

Deaerators are pressure vessels that look like a giant tank car-shaped created to make preheated boiler feed water and boost the efficiency of the boiler’s process. In addition to that, deaerators like tray type deaerator also eliminate carbon dioxide and oxygen. These essential elements of equipment have a variety of sizes, shapes, capacities, and pressure ratings.

Continue reading this article to understand the reasons why every plant needs to use a deaerator for boiler feed water in plants.

Why Do Plants Need Deaerator?

Depending on the size and design of the plant, the value of feed water required could be large or small by size. Particular applications enable the steam to condensate and are recycled back into the boiler vessel and can be utilized as an element of the feed water. Other water comes in as freshwater or makeup.

Whether the makeup comes from a local water utility or water well, the temperature of it will be cold, which contains a lot of oxygen, as well as other dissolved gasses. In spite of the number of condensate returns, the freshwater or the makeup water should be correctly conditioned before it’s processed as feedwater.

Main Objective of Deaerator

Both mechanical and chemical deaeration are essential parts of the current boiler water protection. If the mechanical deaeration is combined with additional external procedure aspects of the chemical deaeration, it gives the ultimate quality feed water for the boiler.

This conditioning method needs to acquire four different objectives:

- To prevent thermal shock from the boiler, it’ll heat the cold water

- Eliminate every dissolved oxygen or gasses to lessen the desire for other types of water treatment chemicals

- Eliminate different types of dissolved gasses to avoid carbonic acid corrosion

- Eliminate any non-condensable gasses to the bolster steam efficiency.

Essential Advantages of Deaerators

Here are the advantages of utilizing deaerators for plants:

- It removes oxygen and carbon dioxide from the feed water and can lessen corrosion

- Boost efficiency from the process of preheating feed water

- It serves as the primary source for the condensate return process

- It gives areas for feeding, blending chemicals, and for testing protocols

- Mix makeup water and hot condensate

- It provides convenient areas for feed water testing

- It can store treated water for load change

- It can deliver continuous pressurized water to boiler feeds

- It aid to make sure that a precise pressure inside the boiler should be level in drum water.

Efficiency of Deaerator

Deaerators are an essential component of a feedwater system for every plant. And at the same time, it is also the primary source of the plant’s thermal-energy and boiler mass-flow database utilized to recognize energy-saving possibilities and evaluation of plant operations.

Continue Reading